SOP: Series Production Start of the AS 990 Tahr RC

With the start of series production, the AS 990 Tahr RC transitions from development project to industrial reality. The SOP marks the completion of a multi-year process involving requirement definition, field validation, engineering optimisation and production planning. The result is a remote-controlled mower engineered for repeatable quality, predictable performance and long-term reliability in extreme terrain applications.

From application analysis to product concept

The development of the AS 990 Tahr RC started with a clear project brief: eliminate turning manoeuvres on steep slopes, increase operational safety and raise measurable area output. Municipalities, infrastructure operators and professional service providers require machines that perform consistently on long, linear slopes where turning represents the highest risk.

This requirement led directly to the concept of bidirectional mowing without turning. Instead of optimising existing RC mower concepts, AS-Motor designed a system that removes the critical operation entirely. The mowing process itself defines the driving logic, not the other way around.

Engineering focus: functional simplicity and system stability

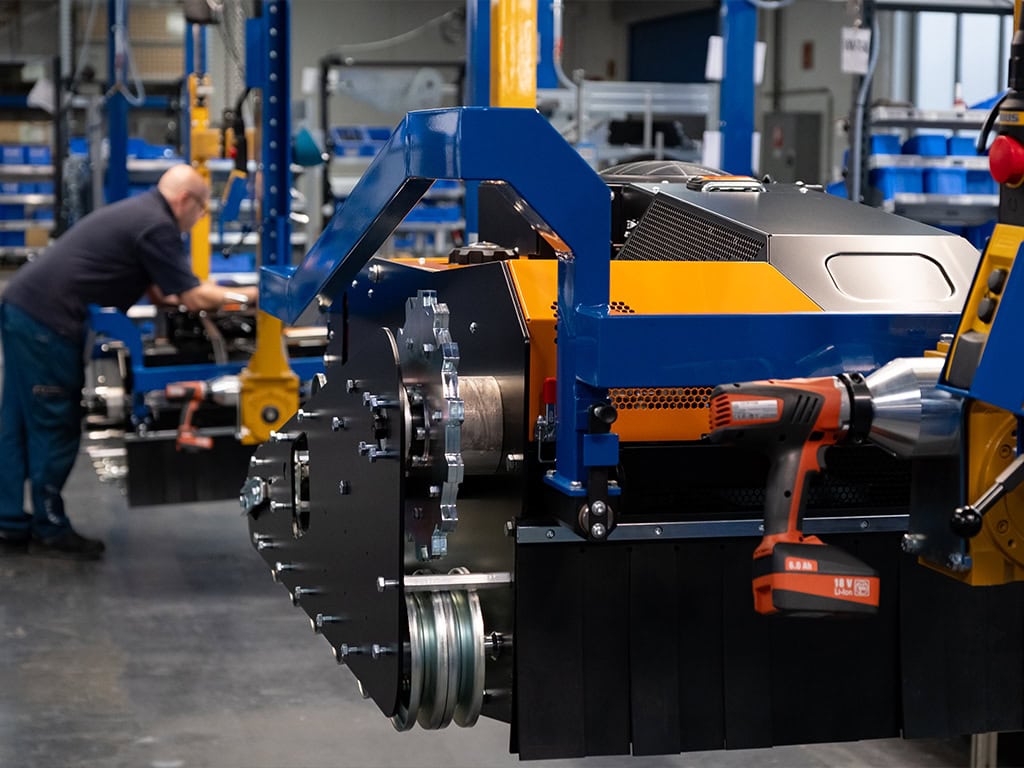

From an engineering perspective, the AS 990 Tahr RC was designed as a closed system with clearly prioritised functions. The symmetrical rotary mower deck delivers identical cutting results forwards and backwards, enabling mowing without turning while maintaining consistent mulch distribution and cut quality.

The tracked chassis was dimensioned around stability and traction rather than speed alone. Balanced weight distribution, a low centre of gravity and a wide track base allow controlled operation uphill, downhill and across slopes. With slope capability up to 56 degrees and ground pressure of just 0.13 kg/cm², the system meets both safety and soil-protection requirements defined at project start.

Design for production and serviceability

SOP readiness required more than functional validation. The AS 990 Tahr RC was engineered for serial manufacturability and long-term service support. The square steel tube frame, proven hydrostatic drive components and mechanically robust mower system reduce complexity across production, service and spare parts logistics.

Service access was integrated into the design phase. A folding engine hood, open machine layout and minimal electronic dependency allow fast maintenance without specialist tools. These decisions shorten service times, reduce training requirements and support predictable operating costs across the machine’s lifecycle.

Defined USPs validated before SOP

All key USPs of the AS 990 Tahr RC were validated before the start of series production. The elimination of turning manoeuvres through bidirectional mowing delivers up to 30 percent time savings on long slopes while removing the most critical safety risk. Area performance of up to 4,500 m² per hour is achieved through continuous operation, not higher travel speed.

Remote-controlled operation keeps the operator outside the danger zone, while mechanical safeguards such as triple discharge protection and automatic parking brake systems ensure compliance with professional safety expectations. Optional LED lighting and clear machine geometry support operation in complex infrastructure environments.

SOP as foundation for scalable deployment

The SOP of the AS 990 Tahr RC establishes a stable platform for scalable deployment across municipalities, infrastructure maintenance and professional service providers. Compact dimensions, defined transport interfaces and predictable performance characteristics allow easy integration into existing fleets and logistics concepts.

Developed and manufactured in Bühlertann, the machine reflects AS-Motor’s approach to project-driven product development: application-first thinking, engineering discipline and solutions designed for real-world constraints. With SOP completed, the AS 990 Tahr RC enters the market as a fully validated tool for safe, efficient and repeatable steep slope mowing.